News & Event

Kiwi’s AIoT Uninterrupted Cold Chain Management Solution Assists On Medical Logistic and Hypermarket/Supermarket Vendors Smart Temperature Management

- 02/19/2021

The COVID-19 epidemic has led to a dramatic loss of human life worldwide, the business operation of many industries has been changed, which has brought many challenges. The demand for digital transformation has driven many companies to accelerate the deployment of AIoT technologies such as Automation, Smart and Intelligence and to solve current and future facing problems in order to ensure the continuity of business development. Industries such as logistics, retail, and pharmaceuticals have been greatly affected by the epidemic and demand for the use of AIoT technology has increased.

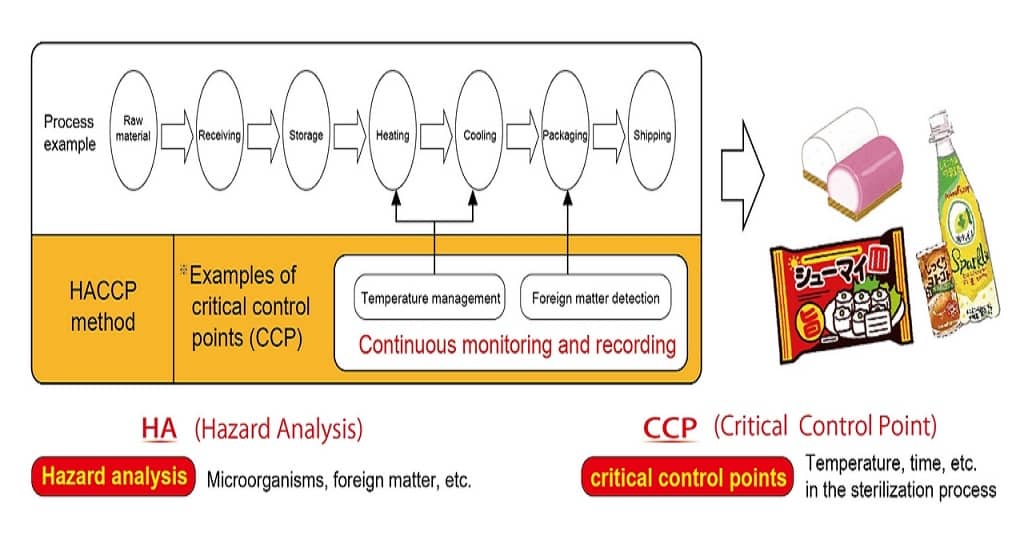

In order to strengthen quality control over frozen and refrigerated products, food in supermarkets to comply with the HACCP regulations of the Food Sanitation Law Amendment issued by the Ministry of Health, Labour and Welfare of Japan in 2018, all related food retail in Japan will be fully enforced from June 2021.

An international top tier hypermarket chain in Japan after the introduced Kiwi Technology’s smart cold chain management solution at beginning of 2020, for food safety purpose, using wireless LoRa temperature sensors to create a surveillance network and system to monitor temperature changes in real time. This way, products can be protected from the risk of spoilage due to fluctuations in temperature.

A numbers of Japanese pharmaceutical warehousing and cold chain vendors and a Taiwanese pharmaceutical cold chain logistics and warehousing vendor had fully introduced Kiwi Technology’s medical cold chain management solutions in early 2021 to respond to the increasingly important medical safety issues of pharmaceuticals and vaccines.

For the pharmaceutical logistics industry, it is necessary to get rid of the old thinking and attitudes of the past. It is necessary to look at the pharmaceutical logistics industry chain from the perspective of the pharmaceutical manufacturer. How to “Uninterrupted” is a big challenge, for medicines and vaccines, The environmental temperature is very sensitive, and if it is slightly inappropriate, it is easy to cause drug inefficiency, failure and economic loss due to a unproper temperature control. In order to fit the special and sensitivity of drugs and vaccines, it is necessary to maintain a stable and high quality environment from storage and transportation. It must be able to track all records 24/7 and provide real-time warning.

Please see the related news reports and website link bellowing

Click to view the related documents in the published text.

https://www.youtube.com/watch?v=ov5Ly06oADw&t=394s

News source: TVBS News